Industry 4.0, Big Data, Internet of Things. There’s a whole range of catchwords for networked, intelligent production. With SOMA, softgate offers a software solution for capturing, evaluating, and visualizing data for the digitization of production equipment. The data sources are virtually unlimited, as are the areas of application. Any machine that either delivers data innately or provides data, for example, using retrofitted sensors, can be connected to SOMA via plug & play and analyzed.

And that is exactly what the catchwords mentioned at the outset are about: Linking machines to powerful IT systems.

Based on the extracted data, these IT systems make it possible to create relationships that allow predictions/trends about machine/tool wear, product quality, and energy consumption.

By using modular hardware, SOMA makes it possible to connect a single machine or even a cluster of machines easily. Central data storage makes configurable comparisons and evaluations possible. The use of state-of-the-art web and security technology allows worldwide access to the captured and analyzed machine data of your production equipment or systems.

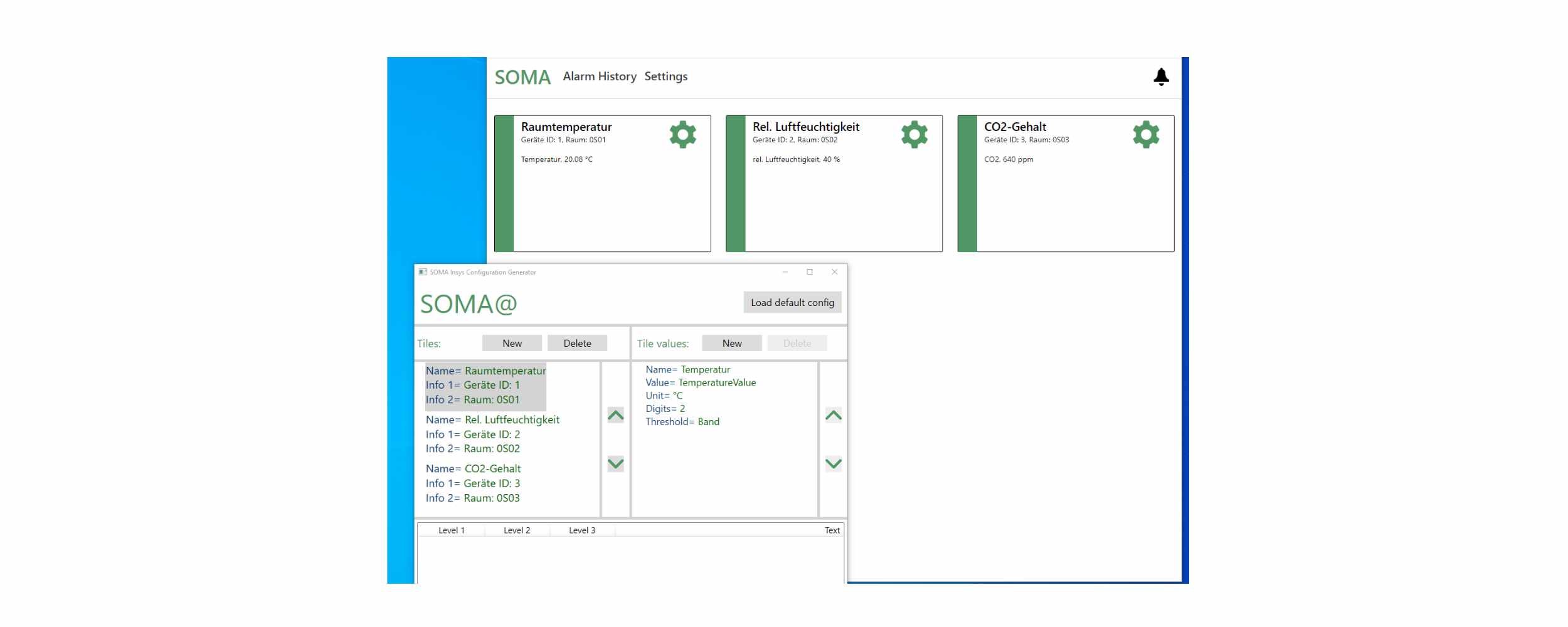

What data visualization looks like with SOMA

Contact us:

My team and I are always happy to help and advise you if you have any questions about SOMA or digitization in industry.